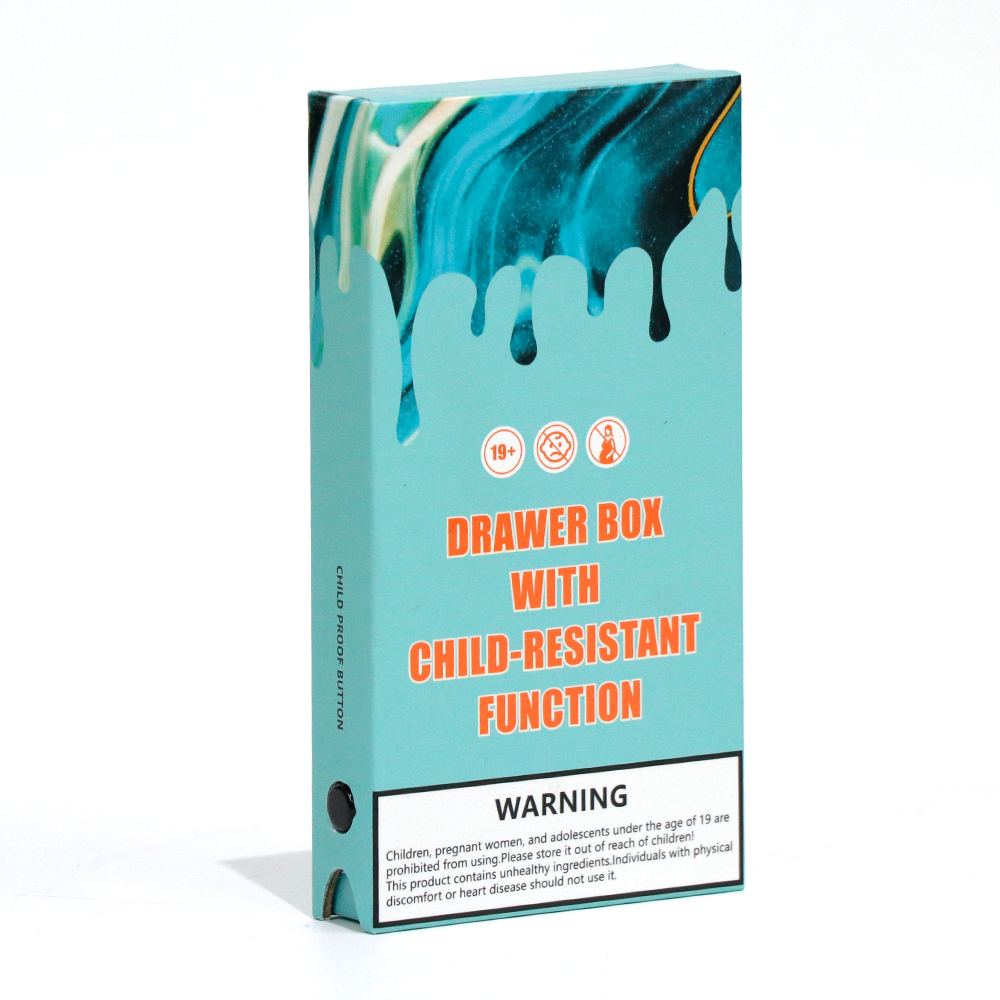

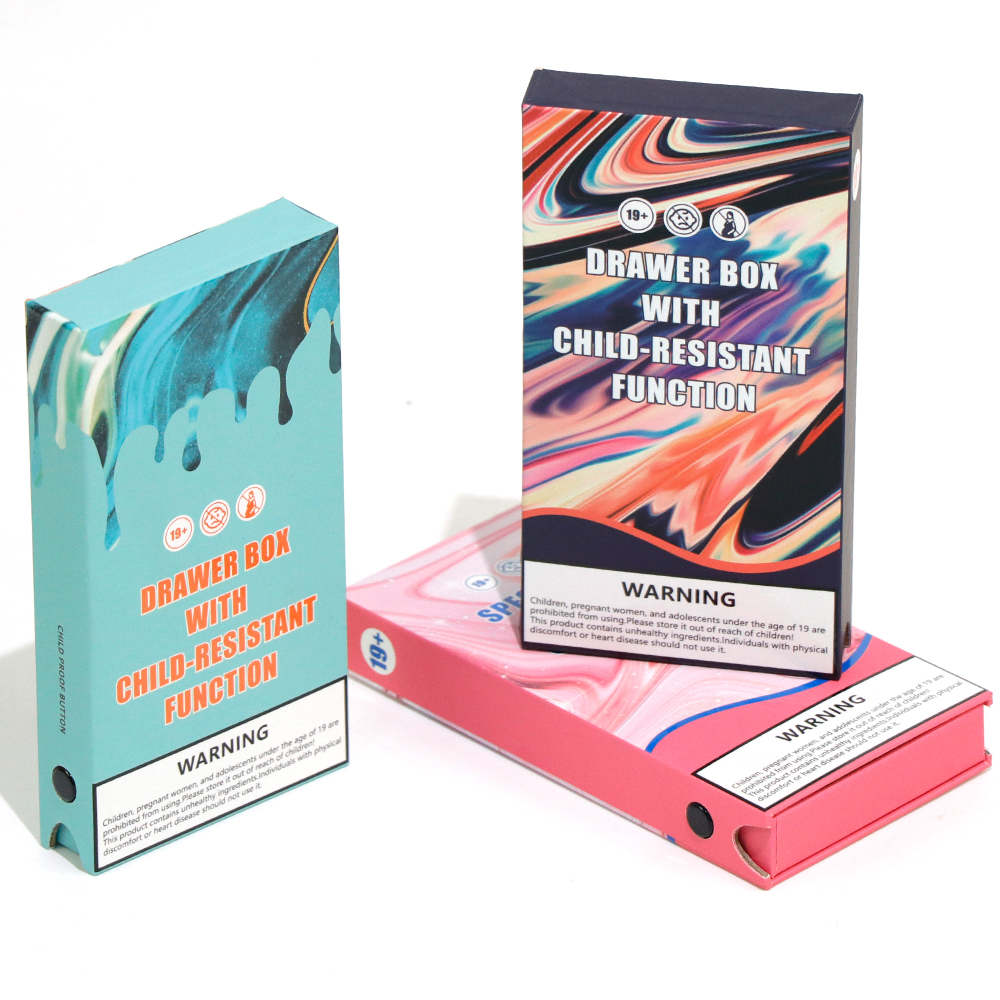

Custom Child Proof 5 Pre Roll Drawer Box Divider Boxes Consultant

Childproof pre-roll drawer box divider box customized consultant service description Based on 16 years of experience in the Cannabis packaging industry, combined with child safety and aesthetic design

Параметри безпеки входу в систему

1. Core product positioning

Specially designed for Cannabis derivatives (CBD/THC/Pre-roll, etc.) High-safety, high-functionality packaging solutions to meet the following needs:

• Childproof certification: Comply with international child safety standards (such as ASTM D4253, CPSC 16 CFR Part 1700), through the compression-resistant and anti-opening structure design, to ensure that children under 5 years old cannot accidentally open.

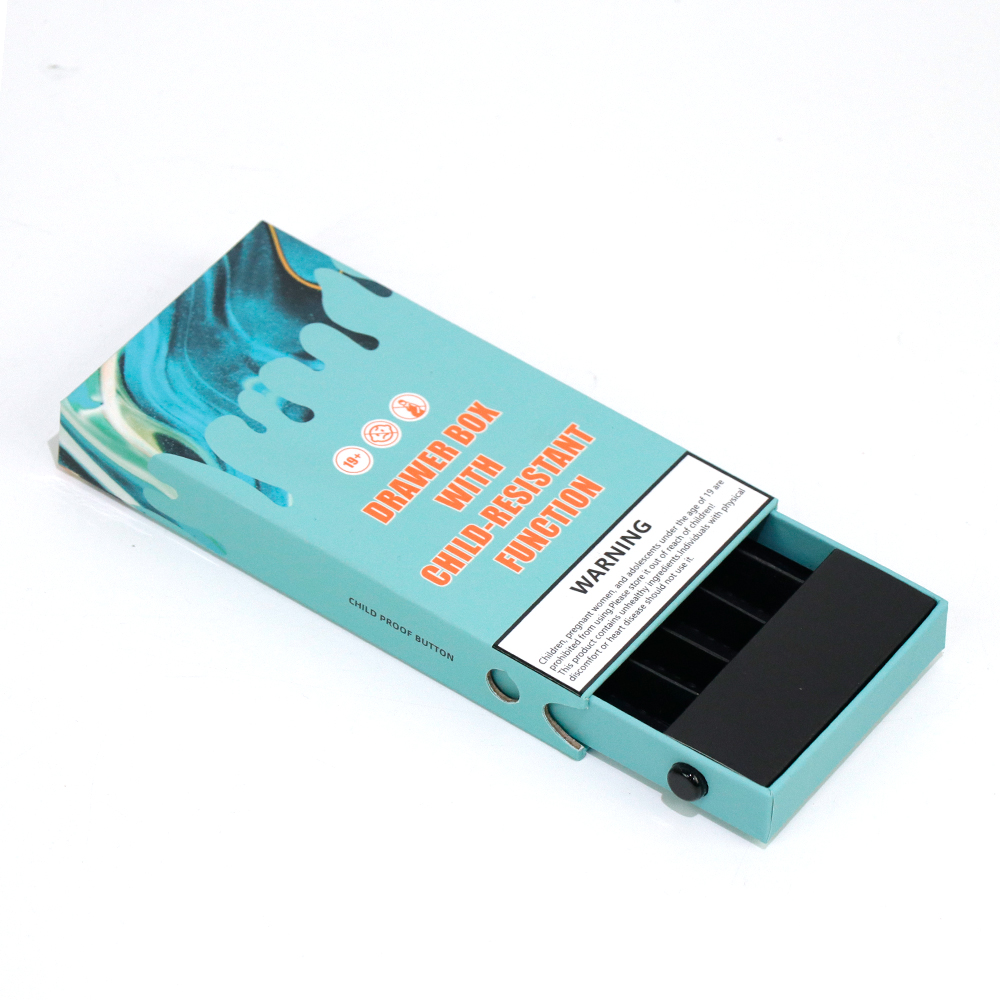

• Pre-roll partition system: Built-in adjustable partition layer, suitable for Pre-roll, Live Rosin and other roll products of different sizes, to avoid shaking and damage during transportation.

• Visual marketing optimization: Through the combination of materials and processes, create a trendy appearance that meets the young consumer group, while avoiding the risk of sensitive logos.

2. Customized box solution

| Box type | Functional characteristics | Applicable scenario case |

|---|---|---|

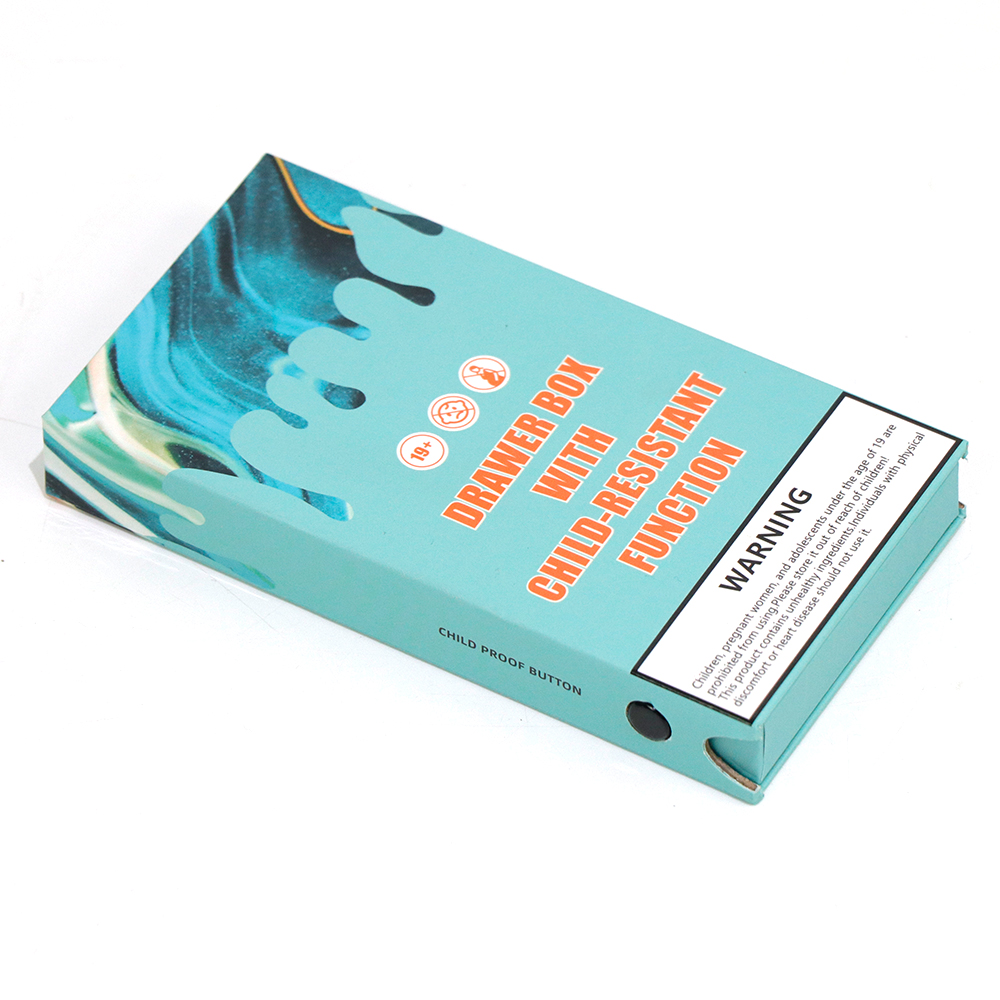

| Child Resistance Rigid Drawer Box | Double-layer locking structure (magnetic suction + buckle), two-handed operation is required to open; drawer slide rail has built-in damping buffer | High-value products such as high-end THC oil, CBD essence, etc. |

| Foldable Magnetic Box | Foldable design saves storage space, magnetic suction flap with hidden lock | Portable Pre-roll multi-pack gift box |

| Clamshell with Child-Resistant Hinge | Hot-pressed flap, integrated child-resistant buckle at the hinge, opening and closing requires force at a specific angle | Large-capacity CBD capsule packaging box |

| Customizable Art Paper Drawer | Using 350gsm art paper + partial UV embossing, the separation layer can be laser engraved with brand LOGO | High-end line products for adults |

3. Innovative combination of materials and processes

Safe material selection • Basic protection layer: Rigid Gray Cardboard (3mm thickness) + child-proof metal loc

• Visual enhancement layer: Holographic Paper (laser color change effect) or Gold Foil Stamping (hot stamping process)

• Environmental protection option: biodegradable PLA material (requires an additional 30 days of production cycle)

Process overlay solution

Example: Child-proof Pre-roll divider

1.Substrate: Art Paper 400gsm (matte surface)

2.Printing: Pantone 802C (warning color) + 6-color CMYK high-precision overprinting

3.Protection: UV Spot coating key areas (anti-scratch)

4.Structure: built-in EVA foam divider, suitable for 5 roll diameter specifications

5.Lock: Hidden magnetic lock (requires 2kg pulling force to open)

4. Cost optimization and delivery process

• Advantages of pre-formed shipment:

• Factory pre-installed partition system, customers only need to fill the product (saving 70% of manual packaging time)

• Provide standardized partition templates (such as 1.5g/3.0g Pre-roll dedicated card slot)

• Quick proofing service: • Provide 3D renderings within 72 hours • Complete the first order production in 15 days (including FDA food grade packaging certification)

5. Market trend insights

• Packaging trends in 2025:

• Emotional design: Enhance the interactive experience through temperature-sensitive ink (touch color change)

• Smart protection: Integrated NFC chip to achieve anti-counterfeiting verification (additional cost $0.8/unit)

• Sustainable packaging: The utilization rate of FSC certified materials increased to 65%

6. Design team service

• Requirements analysis phase: Provide “Cannabis Packaging Compliance Self-Checklist” (including 12 child safety indicators)

• Concept design phase: Output 3 sets of style schemes (minimalist technology style/retro pharmacy style/natural plant style)

• Mass production support: Provide packaging disassembly diagram and filling tutorial (including video demonstration)